Qingdao Hi-Tech Industrial Park Hongkun Rubber & Plastic Co., Ltd.

Office address: Room 801, Block B, Yinshengtai New Space, No. 6 Cuiling Road, Laoshan District, Qingdao City, Shandong Province

Phone: 0532-88913480

Fax: 0532-88919963

Qingdao Hongkun Precision Co., Ltd.

Address: Xingling Road, Lingshan Town, Jimo District, Qingdao

Phone: 0532-84531811

Fax: 0532-84531900

General Manager: 13906426837

Track sales: 18753217799

Conveyor belt sales: 13156890560

URL:http://www.hongkunrubber.com

Company email: qdhkjg@163.com

Bucket elevator beltIt is a belt used to convey materials vertically, which is widely used in building materials, mining, chemical, light industry, machinery, electricity, food and other industries.

Features:

Bucket elevator has low belt elongation, large conveying capacity, stable operation, convenient maintenance, and good adaptability to bulk materials. This special belt is completely different from traditional steel belts in terms of thickness, steel wire density, warp and weft arrangement, and steel wire thickness. This kind of belt forms a steel frame in both the vertical and horizontal directions,Therefore, the safe connection of the hopper and the balanced distribution of the load can be guaranteed. The belt is punched mechanically, and the holes have been punched before leaving the factory. Application results show that this special steel wire belt fully meets the requirements of large conveying capacity and ultra-high lifting.

In recent years, our company's researchers have continued to tackle key technical problems and improve the original formula, raw materials and processing technology. The newly-developed steel wire rope bucket elevator belt has a higher instantaneous temperature resistance, which can reach 180 ℃ in an instant, making the N-TGD elevator suitable for high-temperature powdery material transportation links, such as: slag grinding, cement grinding, cement storage and Transportation of materials such as fly ash.

N-TGD wire rope belt bucket elevator

N-TGD steel wire rope belt bucket elevator (hereinafter referred to as: N-TGD) has the characteristics of large conveying capacity, small size, low power consumption, stable and reliable operation, long service life, and can achieve ultra-high lifting of a single machine. This machine is suitable for vertical transportation of bulk materials or small particles. It is widely used in high-load conveying systems for powder and granular materials in cement, alumina, fertilizer, coal, power, ports, and grain industries. It completely replaces imported equipment of the same specification. The cement plant is mainly used in the vertical transportation of the following powder materials.

1: Conveying raw materials into the kiln;

2: Conveyance of incoming raw materials and incoming cement;

The N-TGD high temperature resistant steel wire rope belt bucket elevator is superior to the plate chain elevator in terms of operating consumption, operating reliability and service life.

1: Raw material is ground out and the material is conveyed;

2: Cement grinding material conveying;

3: Material transportation of cement packaging system;

4: The slag grinding system conveys the grinding materials;

About N-TGD technical indicators

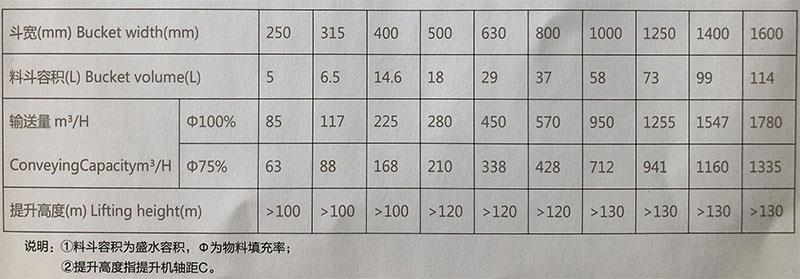

The lifting height of a single machine exceeds 130 meters;

The conveying capacity of a single machine exceeds 1335m3/h;

The belt has an instant heat resistance of 180°C;

N-TGD technical characteristics

It adopts a number of patented technologies with independent intellectual property rights, and all technical indicators are equivalent to imported similar equipment and exceed similar foreign equipment.

The traction parts adopt high-strength patented steel wire tape;

Adopt special material belt clip, with excellent fatigue resistance;

The tape joint adopts special locking technology;

The head wheel adopts a tile-type coating structure, which is easy to replace;

Self-balancing tension device, automatic tension, automatic correction;

Equipped with material level controller, conveyor belt swing detector and speed detector for selection;

The hoppers are closely arranged to continuously extract and discharge materials.

Specification model:

Previous: Large dip